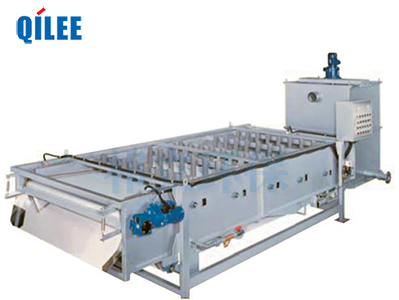

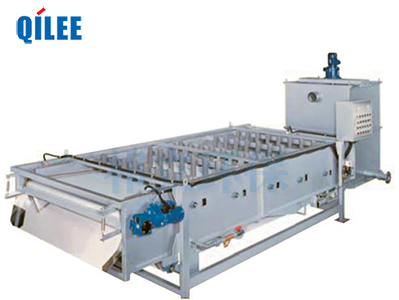

Before operation, the sludge thickener shall conduct a comprehensive inspection of the whole machine. It is forbidden to start up the plant when the number of filter plates is less than the specified number. It can reduce capital investment and land occupation, and reduce the emission of odor and phosphorus. Here is a detailed introduction to "maintenance and advantages of sludge thickener".

1、 Maintenance of sludge thickener

1. The feeding work can only be carried out after commissioning the normal filter press, and the whole machine shall be comprehensively inspected before each shift. Sufficient lubricating oil shall be added to the mechanical compression transmission parts and reduction gearbox; Recheck the oil storage capacity of the oil tank and the working pressure of the hydraulic station. The hydraulic oil is generally replaced once a year. During replacement, the hydraulic system shall be fully cleaned. The working pressure of the hydraulic station is less than the high working pressure of the oil cylinder, but it shall not be lower than the allowable value of the filter pressure. If it is too small, it will cause large leakage and damage the parts.

2. It is forbidden to start the machine in the factory when the number of filter plates is less than the specified number, so as not to damage the parts. Check the arrangement of filter plates before feeding, and the filter cloth shall not be folded to prevent large leakage; After cake unloading, the filter plates must be tightly pressed and arranged in order.

3. After everything is normal, the filter plate can be pressed for pressure filtration. The filtration pressure and temperature must be within the specified range. If the filtration pressure is too high, there will be leakage. If the filtration temperature is too high, the plastic filter plate is easy to deform, and the suspension concentration shall be uniform during feeding. No sundries; After cake unloading, the filter cloth and filter plate must be washed clean, and the residue is not allowed to stick in the sealing surface or feed channel, otherwise it will affect the smooth feed and the tightness of the filter plate, resulting in the unbalanced pressure on both sides of the filter plate, resulting in the deformation and damage of the filter plate.

4. The selection of sludge thickener must meet the filtering technical requirements of the filter paddle. The new filter cloth shall be shrunk before making, and the opening diameter shall be less than the filter plate aperture. When matching the filter plate, the distribution hole and the plate aperture shall be relatively concentric, and the feed hole cloth shall be close to the cylinder wall, otherwise, it will cause unclear filtration, low filtration rate, rupture of the distribution cylinder, and failure to achieve the expected filtering purpose.

5. At the initial stage of pressure filtration, the filter of sludge thickener is turbid. When a - layer of filter cake is formed on the filter cloth, the filtrate will become clear. If the filtrate is always turbid or becomes clear and mixed, the filter cloth may be damaged or the layout hole deviates from the plate hole. At this time, close the valve or stop feeding and replace the filter cloth. A small amount of leakage caused by capillary phenomenon of filter cloth is allowed between filter plates.

6. When moving the filter plate, the force shall be uniform and appropriate, and shall not collide or fall, so as not to damage the sealing surface and filter wrench handle. The filter cloth will harden and its performance will decline after being used for a period of time. Therefore, regular inspection is required. If changes affect the filtration rate, neutralize and clean it with corresponding low concentration of weak acid and weak alkali to restore the function of the filter cloth. If it cannot be restored, replace it in time.

2、 Advantages of sludge thickener

1. Reduce infrastructure investment and land occupation

2. Reduce odor and phosphorus emissions

3. Reduce the burden of subsequent treatment

4. Increase the capacity of sludge dewatering or deep dewatering equipment

The above is the introduction of "maintenance and advantages of sludge thickener". Please feel free to contact us if you have any questions.

Service hotline:

Service hotline:

Español

Español

ภาษาไทย

ภาษาไทย

عربي ،

عربي ،

русский язык

русский язык

Portugiesisch

Portugiesisch

Vietnamese

Vietnamese