Sludge thickener is widely used in industry, but it is mainly used for the treatment of sludge and sewage in the pool, which is very popular in industry. There are many matters needing attention in the specific application. I believe many friends are not very clear about the structure and characteristics of the main components. This paper will share some matters needing attention in the start-up of sludge thickener and its structural composition What are the contents? I hope you can like them.

1、 Precautions for start up of sludge thickener

1. Fill the tank with clean water to ensure the commissioning and smooth operation of the central drive thickener;

2. Start the button switch to start the car. When the switch operates normally, the sewage can be discharged;

3. The machine is equipped with over-current protection device, which can stop immediately in case of failure to protect the motor safety;

4. If it is difficult to start the machine again, the sludge at the bottom of the central drive thickener should be removed and the motor should be started after confirming that there is no obstruction of sludge scraping;

5. The central drive sludge thickener is a continuous working system. After a long-time shutdown in case of failure, it is necessary to prevent and control the sewage in the tank and manually remove the deposited sludge before it can be put into use again;

6. Sleep in the pool should be frozen after thawing or breaking the ice. Don't talk about stones and other debris falling into the pool.

2、 Structure and characteristics of main components of sludge thickener

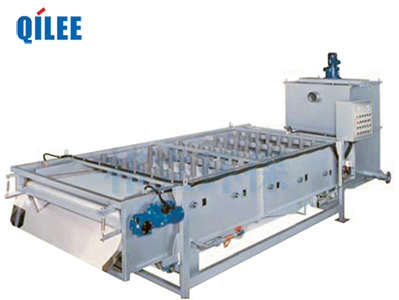

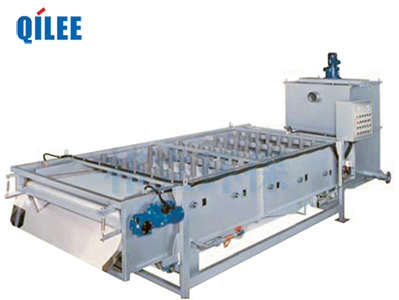

The thickener consists of five parts: concentration tank, specially designed large torque water type bridge, main transmission mechanism, lifting mechanism and slag rake.

1. Main drive mechanism the main drive mechanism is a system that drives the rake frame to rotate. It is mainly composed of motor, cycloid pin gear reducer and main worm gear pair. In order to ensure the need of lifting the rake frame in operation, the worm gear and the vertical shaft are connected by splines. Under normal working conditions, the vertical shaft can move up and down freely.

2. If the thickener is overloaded during the operation of the hoist and the torque measuring switch protection device, the hoist can lift the slag rake by moving the vertical shaft in series to ensure the safe operation of the machinery. Its main structure consists of two parts: a specially designed and manufactured torque measuring switch, an alarm, a control device and an actuator.

3. The sludge thickener is generally composed of thickening tank, cake rack, transmission device, cake rack lifting device, feeding device, discharging device and signal safety device. When the thickener is working, there is a discharging hopper discharging concentrated products in the center of the bottom of the tank, and there is an annular overflow tank around the commercial port of the tank.

That's what I'm going to share with you today about the matters needing attention in starting up the sludge thickener, what are the contents of the structure composition, and more problems can continue to pay attention to us.

Service hotline:

Service hotline:

Español

Español

ภาษาไทย

ภาษาไทย

عربي ،

عربي ،

русский язык

русский язык

Portugiesisch

Portugiesisch

Vietnamese

Vietnamese