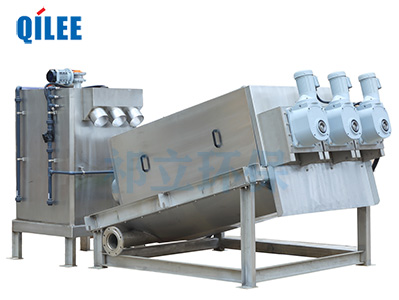

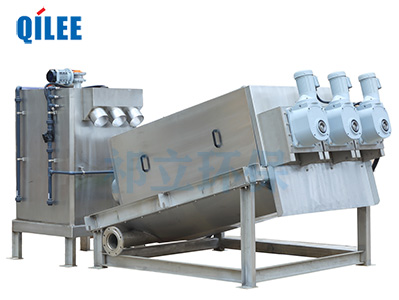

The screw stacker is applicable to the dewatering of high and low concentration sludge, and the treatment is stable and timely, so as to reduce the on-site odor to a very low level and reduce the labor intensity of operators. The following describes the "technical advantages and types of screw stacker".

1、 Technical advantages of screw stacker

1. The screw stacker is suitable for dewatering high and low concentration sludge. When dewatering low concentration (2000mg / L) sludge, there is no need to build concentration tank and storage tank, so as to reduce the construction cost, reduce the release of phosphorus and the generation of anaerobic odor.

2. No blockage, reduce flushing water consumption, save water cost and reduce the burden of internal circulation caused by backflow of cleaning water.

3. The electric control cabinet, flocculation mixing tank and dehydration main body are integrated, which reduces the floor area and is simple and convenient to install.

4. The dehydrator is basically in closed operation, and the treatment is stable and timely, so as to reduce the on-site odor to a very low level and improve the working environment of workers.

5. Realize full-automatic 24-hour operation and reduce the labor intensity of operators.

6. The running speed of screw shaft is low, 2-3 revolutions per minute, low power consumption, and there is basically no vibration and noise on site.

7. Almost all the body is made of stainless steel, which can greatly prolong the service life. Only the spiral shaft and traveling ring are replaced, which has a long service life.

8. The daily maintenance time is short and the maintenance operation is simple.

2、 Type of screw stacker

1. Plate and frame sludge dehydrator equipment

In the closed state, the sludge pumped by the high-pressure pump is squeezed by the plate and frame, so that the water in the sludge is discharged through the filter cloth, so as to achieve the purpose of dehydration.

2. Belt sludge dehydrator

The sludge layer is entrained by the upper and lower tensioned filter belts and passes through a series of regularly arranged roller cylinders in an S-shape. The pressing and shear force of the sludge layer is formed by the tension of the filter belt itself to squeeze out the capillary water in the sludge layer, so as to realize sludge dewatering.

3. Centrifugal sludge dehydrator

It is composed of a transfer and a screw conveyor with a hollow rotating shaft. The sludge is sent to the drum by the hollow rotating shaft, and is immediately thrown into the drum cavity under the centrifugal force generated by high-speed rotation. Due to different specific gravity, solid-liquid separation is formed. Driven by the screw conveyor, the sludge is transported to the cone end of the drum and continuously discharged from the outlet.

The above is the introduction of "technical advantages and types of screw stacker". Please feel free to contact us if you have any questions.

Service hotline:

Service hotline:

Español

Español

ภาษาไทย

ภาษาไทย

عربي ،

عربي ،

русский язык

русский язык

Portugiesisch

Portugiesisch

Vietnamese

Vietnamese